Energy – United States

Reducing energy on the farm and in the supply chain

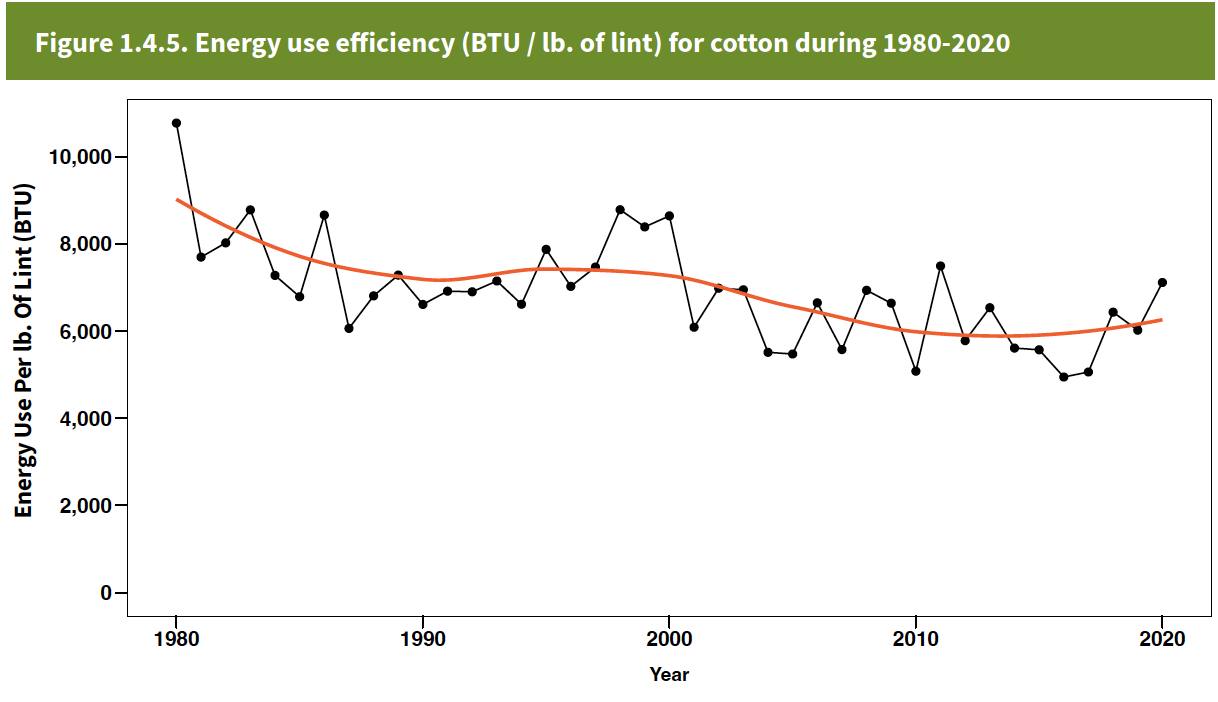

Comparing data for 1980 and 2020, U.S. cotton energy use efficiency has improved by nearly 31%1 – meaning less energy is required per pound of cotton lint produced. This significant change is due to more efficient harvest and ginning technologies, increasing yields, reduced fertilizer applications per pound of fiber, and the adoption of reduced tillage. These advancements in equipment and practices help growers use less fuel while also helping them optimize their use of inputs like fertilizer and herbicides.

The top three contributors to the U.S. cotton industry’s energy use between 2010 and 2020 were farm management (which includes fuel required to operate tilling, harvesting and ginning equipment), fertilizer production and the manufacture of pesticides and other crop protectants.2

U.S. cotton growers and ginners are working toward an industry-wide goal to decrease energy use by 15% between 2015 and 2025.

As U.S. cotton growers and ginners strive to meet the industry-wide energy goal, the pathway to further reductions will be primarily addressed in three ways:

- Increasing the precision of fertilizer applications

- Encouraging more growers to employ reduced tillage

- Continuing to research emerging, energy-efficient farming and ginning technologies

This data from the Field to Market 2021 National Indicators Report shows an overall improvement in cotton energy use efficiency per pound of lint harvested. The slight regression this graph shows between 2016 and 20203 coincides with a dip in the national cotton yield due largely to extreme weather events.

Optimizing fertilizer use to improve energy use

Fertilizer production is the single largest contributor to the U.S. cotton energy footprint; in 2020, it accounted for about 52% of the energy use per pound of lint.4 Nitrogen fertilizer is also a vital input for healthy cotton plants that produces an optimum yield and can be more resilient to stressors, including drought. It is not economically viable for growers to simply stop using it, so U.S. researchers are actively exploring new ways to continue to improve efficiency and reduce fertilizer losses by applying precisely the right amount at the right time.

Cotton Incorporated is leading agronomists and soil fertility specialists in these research efforts. There are many research projects currently underway, and new studies launch each year focused on nutrient use efficiency – with a special focus on how to help cotton plants use nitrogen more effectively. The Beltwide Nitrogen Refinement study, for example, involved field trials in 60 locations over three years; data analysis and modeling are happening in 2023. Another partnership with Louisiana State University is addressing nutrient use efficiency as it relates to that state’s unique soil and environmental conditions.

Going forward, more funding is also being directed toward soil microbial studies that will focus on how the microbiome may be used to improve nutrient use efficiency.

Nutrient management is also a common theme in outreach efforts. Researchers, university extension agents and industry organizations promote this information to cotton growers around the nation.

All of these efforts to use nitrogen more precisely are helping the industry move toward its energy reduction goal – and helping the industry reduce greenhouse gas emissions.

Reducing tillage

To control weeds and diseases, producers traditionally incorporated all crop residues and weeds into the soil surface before planting, and then continued to till the soil throughout the growing season. Growers who use conservation tillage reduce the number of times they plow the soil, which preserves crop residue on the surface of the fields and armors the soil surface. No-till is a form of conservation tillage in which the grower doesn’t plow the fields at all. Both practices significantly reduce fuel use while decreasing erosion and supporting soil health.

As the 2021 National Indicators Report states, research into new technologies as well as social science and community support/outreach will be equally critical for driving reduced tillage practices across the remainder of cotton acreage – and thus driving ongoing reductions in fuel requirements in the field.5

Emerging technologies

The U.S. industry is researching several promising technologies that will reduce harvesting and ginning energy consumption. These technologies, which are expected to become available over the next two decades, include the ability to use gene editing to develop cotton varieties that require less energy to gin.6

These technologies also include advancements in equipment. Research at this time is exploring multi-purpose autonomous units that are much smaller and more efficient than standard harvesters, planters and other machinery. These autonomous units can be all-electric, giving more growers the opportunity to lessen their dependence on fossil fuels. In addition to the potential for reducing fuel use, machine vision-based implements are also under development to aid growers in precision fertilizer applications.

Energy for ongoing progress

The U.S. cotton energy reduction achieved since 1980 is a significant win. Both growers and researchers continue to pursue new methods to reduce energy use on the farm and at the gin – and work toward the U.S. cotton energy goal of an additional 15% reduction.

Energy use is closely connected to other industry impacts. Ongoing progress in energy efficiency will spur progress toward other important goals as well, including the greenhouse gas emission reduction goal.

1 Field to Market: The Alliance for Sustainable Agriculture. (2021). Environmental Outcomes from On-Farm Agricultural Production in the United States. National Indicators Report, fourth edition.

2 Field to Market: The Alliance for Sustainable Agriculture. (2021). Environmental Outcomes from On-Farm Agricultural Production in the United States. National Indicators Report, fourth edition.

3 Field to Market: The Alliance for Sustainable Agriculture. (2021). Environmental Outcomes from On-Farm Agricultural Production in the United States. National Indicators Report, fourth edition.

4 Field to Market: The Alliance for Sustainable Agriculture. (2021). Environmental Outcomes from On-Farm Agricultural Production in the United States. National Indicators Report, fourth edition. Derived from Table 1.2.1 and Figure B.14.

5 Field to Market: The Alliance for Sustainable Agriculture. (2021). Environmental Outcomes from On-Farm Agricultural Production in the United States. National Indicators Report, fourth edition.

6 National Cotton Council, Cotton USA, and Cotton Incorporated. (2018). U.S. Cotton Ten-year Sustainability Goals: Pathways to Progress.

Continue Reading:

Explore the research and resources we’ve pulled this information from.